Click or Scroll Down

PICTURES AND DESCRIPTIONS OF THE MOLD TYPES

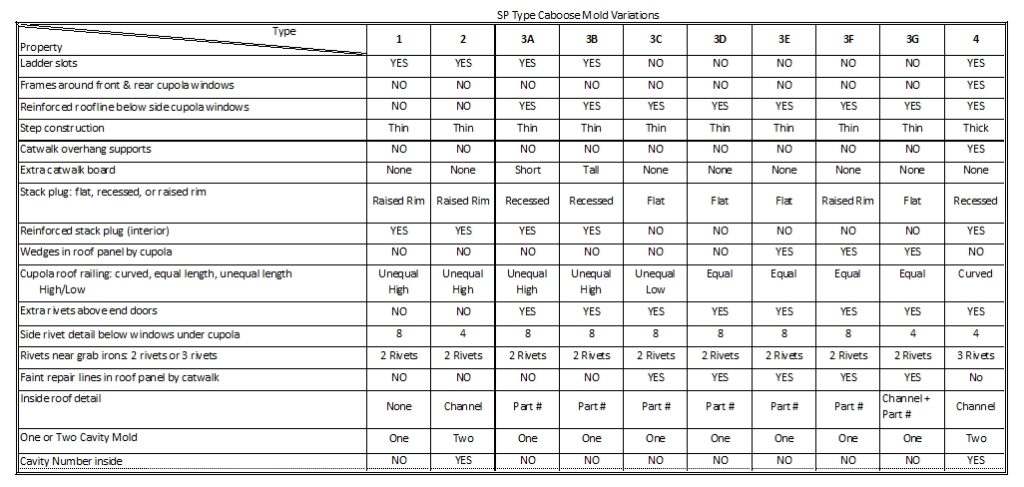

Downloadable Chart summarizes the above shell types

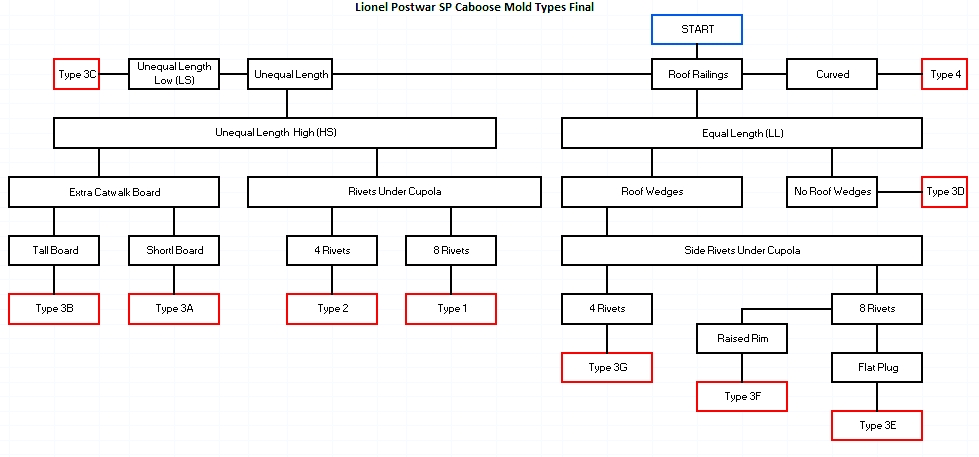

Downloadable Flow chart that will guide in ascertaining the type of a shell

A STUDY ON WHETHER RIVETS TOUCH RAILINGS ON THE LOWER CORNERS OF CABOOSES

Other general information

MOLD TYPES

Click or Scroll Down

TYPE 1

TYPE 2

TYPE 3A

TYPE 3B

TYPE 3C

TYPE 3D

TYPE 3E

TYPE 3F

TYPE 3G

TYPE 4

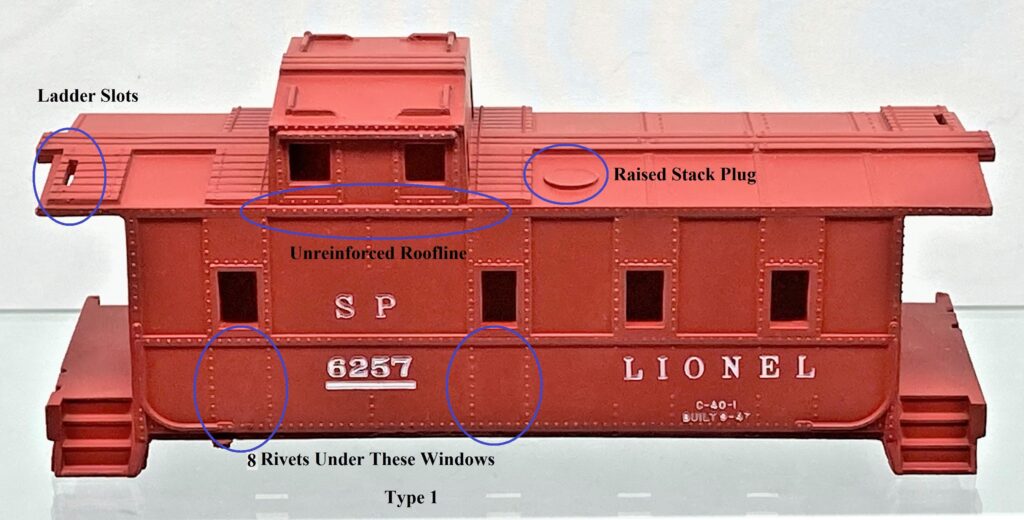

TYPE 1 1947 – 1956

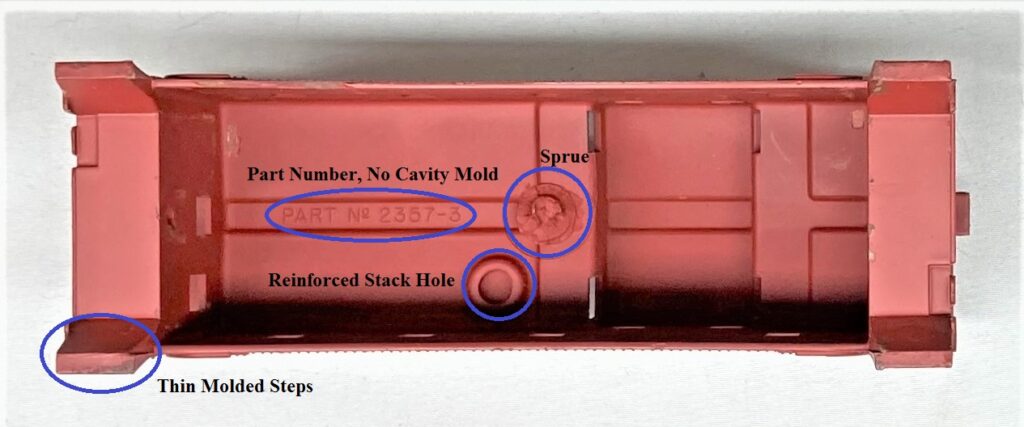

produced in a single cavity mold

comes painted & unpainted

– has ladder slots

– has raised stack plug

– has unreinforced roofline

– has eight rivets in each of the four row under the first two window from the left

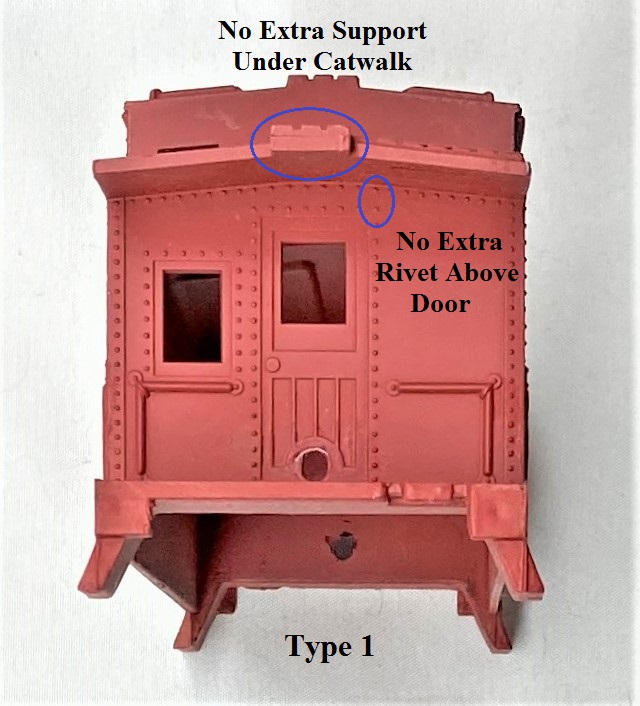

no extra rivet above door

no extra support under catwalk

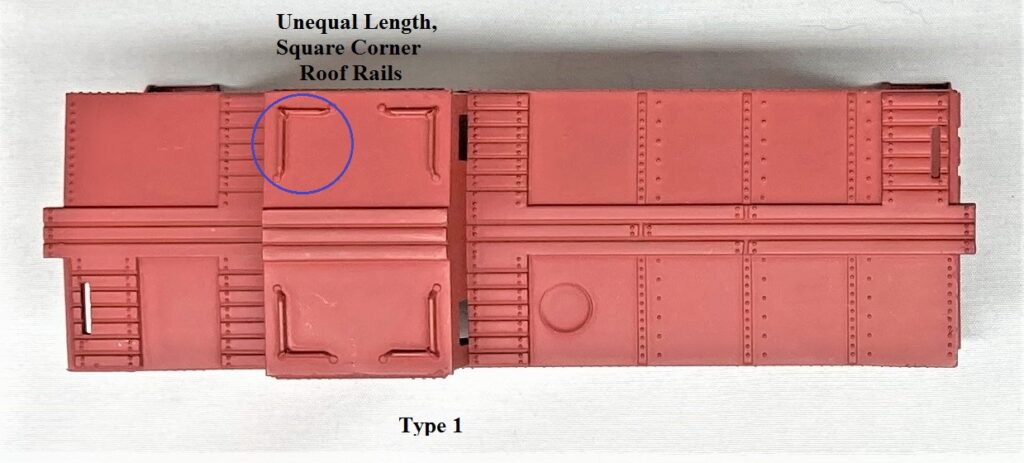

has unequal length railings meeting at right angels

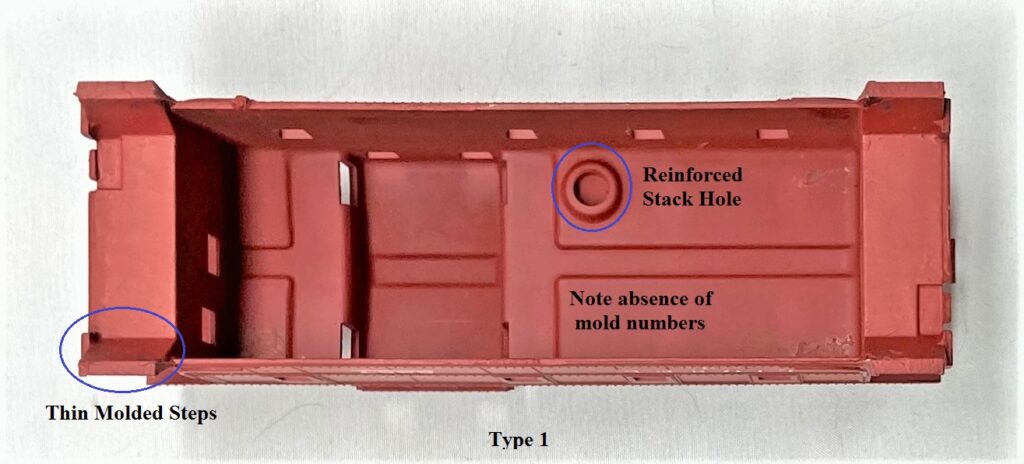

has reinforced stack hole

thin molded steps

note the absence of mold cavity number present when a two cavity mold is used

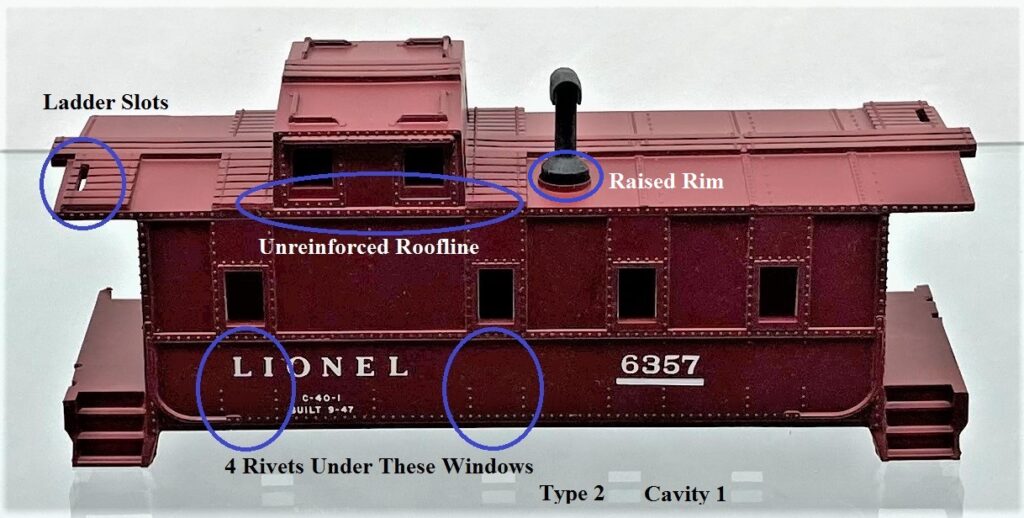

TYPE 2 cavity 1 1957 – 1959

produced in a two cavity mold

comes painted and unpainted

– has ladder slots

– has raised stack plug

– has unreinforced roofline

– has four rivets in each of the four row under the first two window from the left

no extra rivet above door

no extra support under catwalk

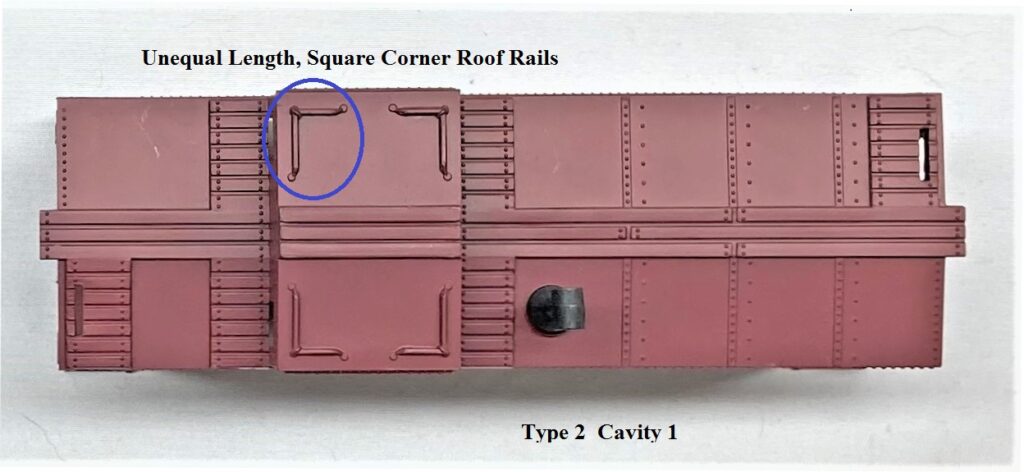

has unequal length railings meeting at right angels

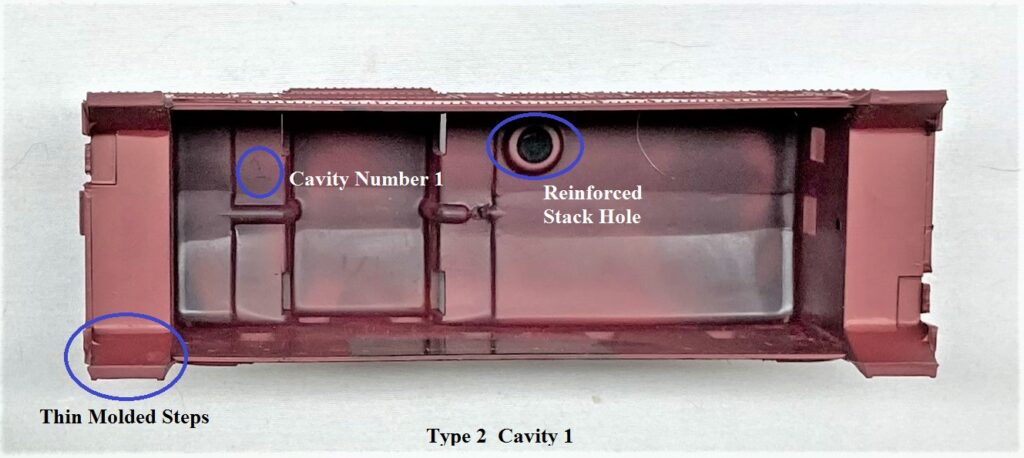

has reinforced stack hole

thin molded steps

note the mold cavity number (1) in this case present when a two cavity mold is used

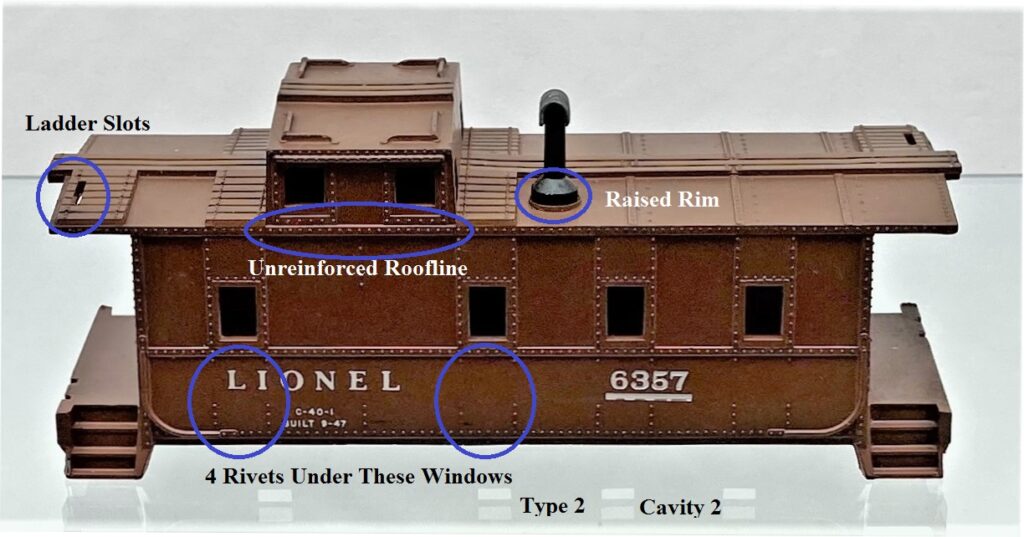

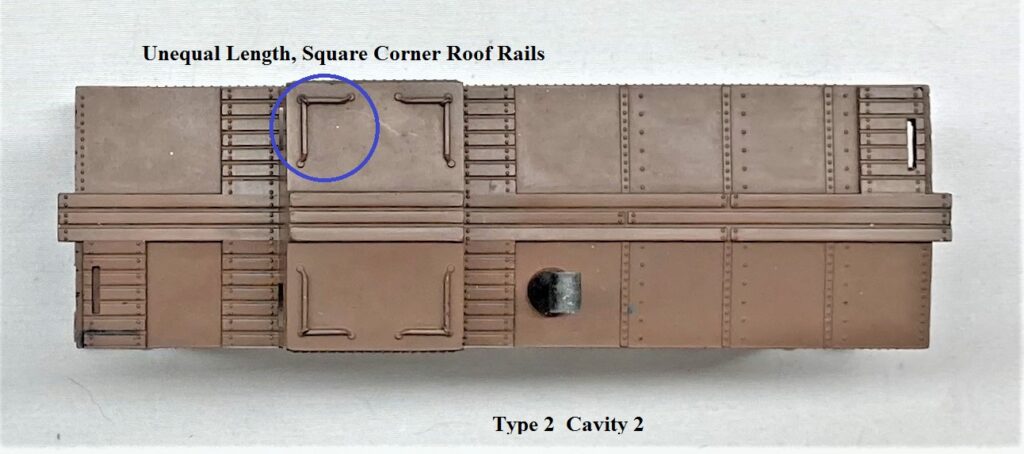

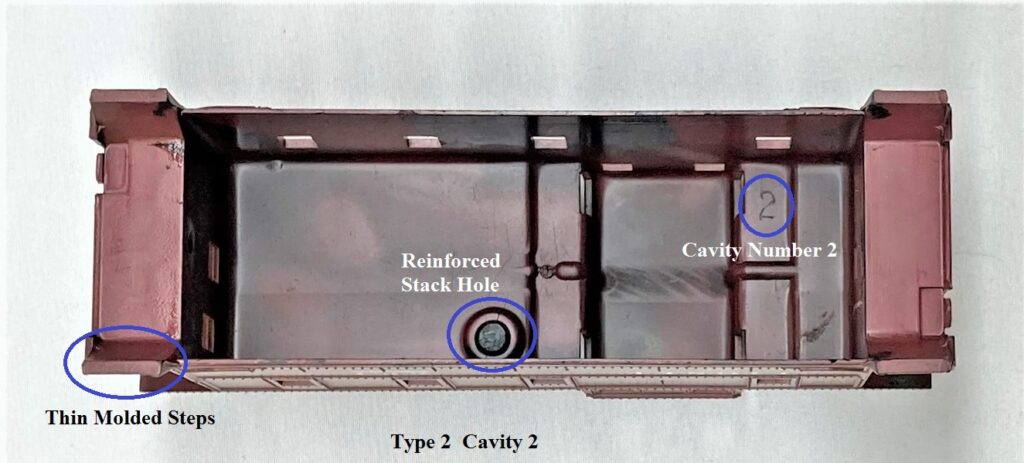

TYPE 2 cavity 2 1957 – 1959

produced in a two cavity mold

comes painted and unpainted

– has ladder slots

– has raised stack plug

– has unreinforced roofline

– has four rivets in each of the four row under the first two window from the left

no extra rivet above door

no extra support under catwalk

has unequal length railings meeting at right angels

has reinforced stack hole

thin molded steps

note the mold cavity number (2) in this case present when a two cavity mold is used

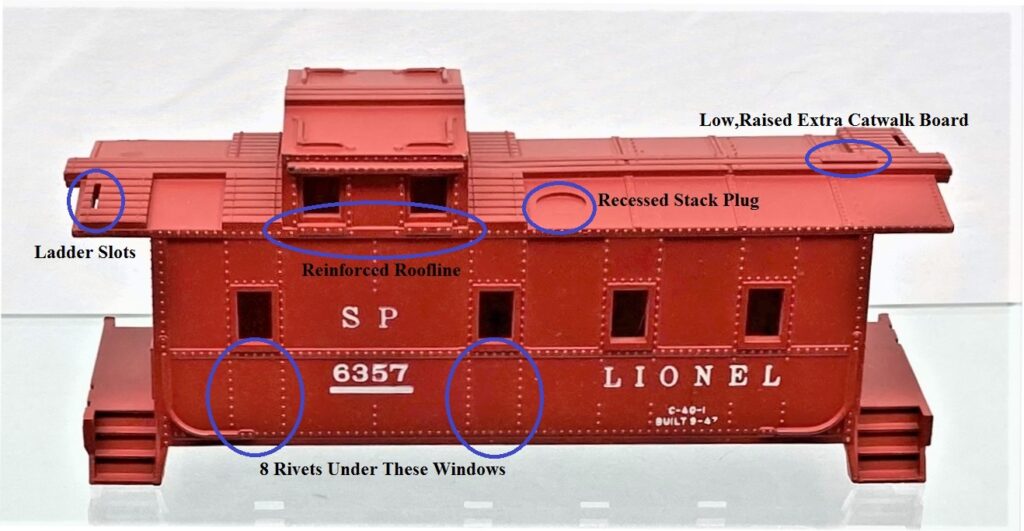

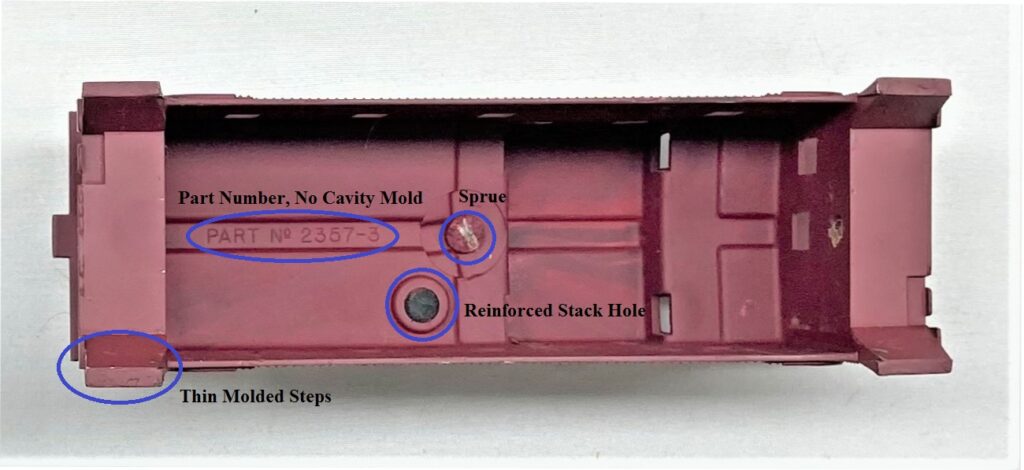

TYPE 3A 1947

produced in a single mold

comes painted and unpainted

low, raised extra catwalk board

– has ladder slots

– has recessed stack plug

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

has unequal length railings meeting at right angels

has part number, no cavity mold number

has sprue

has reinforced stack hole

has thin molded steps

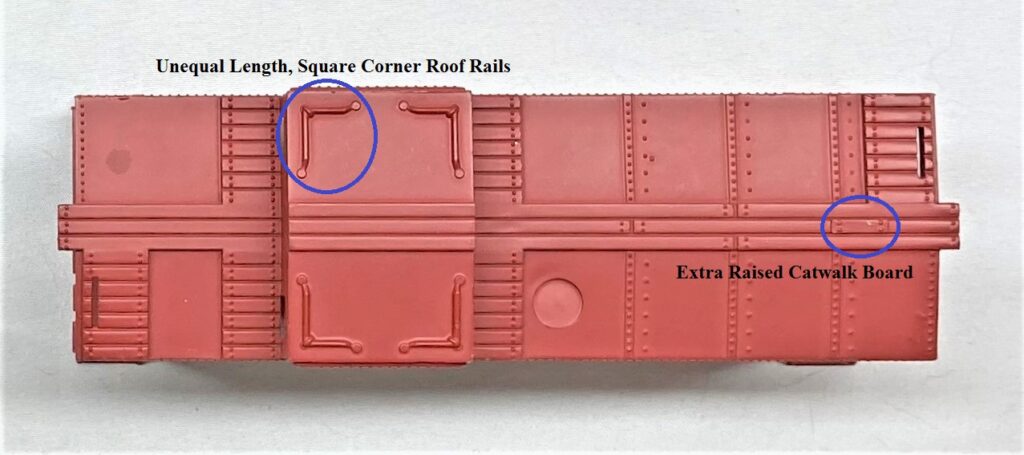

TYPE 3B 1948

produced in a single cavity mold

comes painted and unpainted

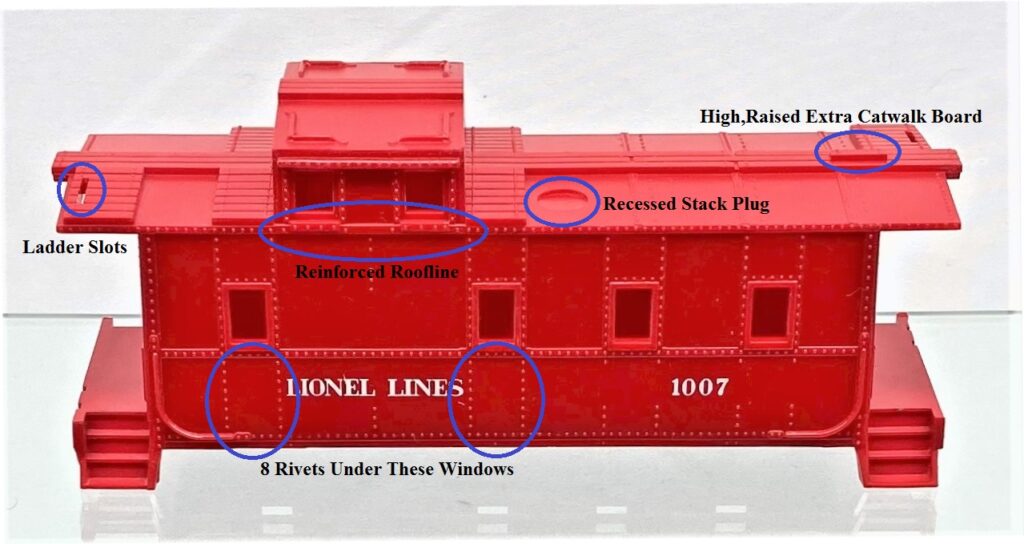

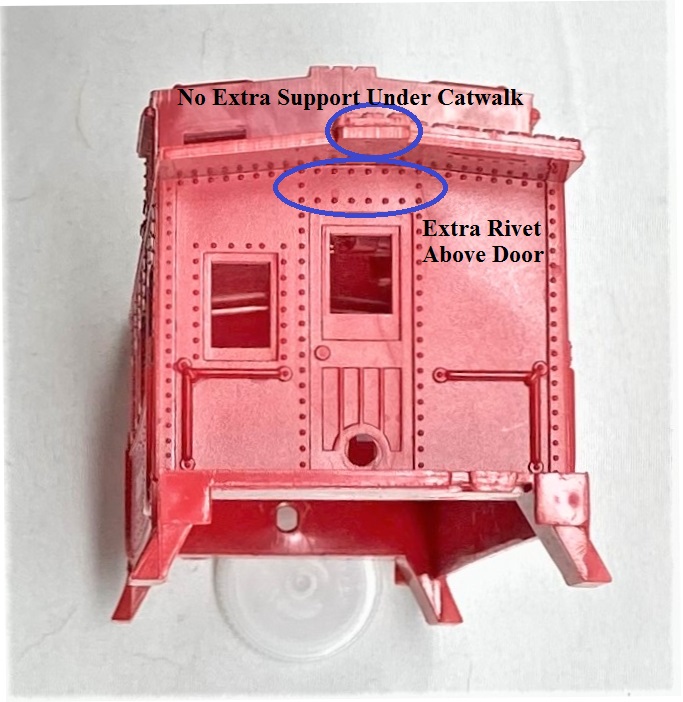

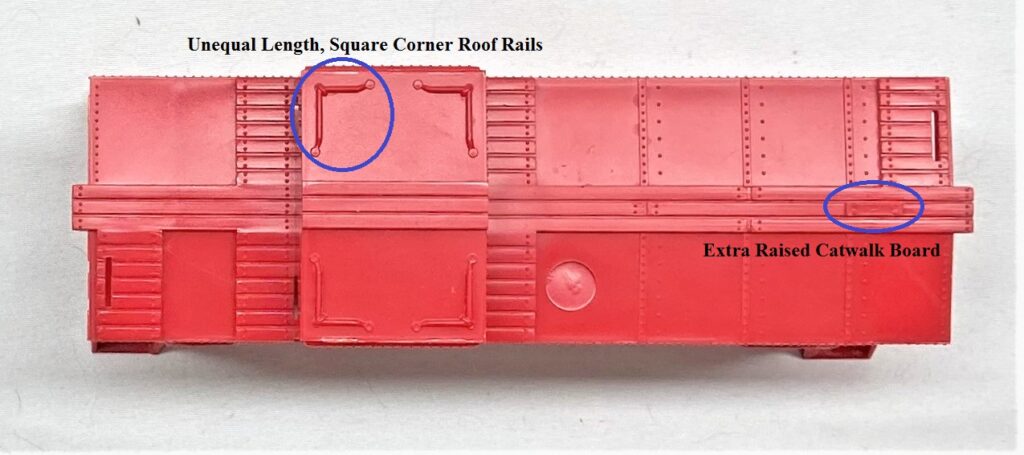

high, raised extra catwalk board

– has ladder slots

– has recessed stack plug

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

has unequal length railings meeting at right angels

has part number, no cavity mold number

has sprue

has reinforced stack hole

has thin molded steps

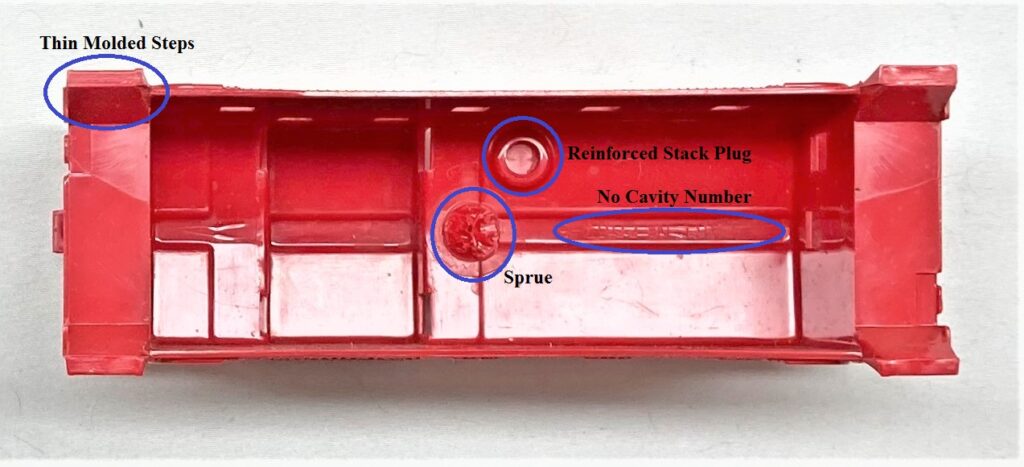

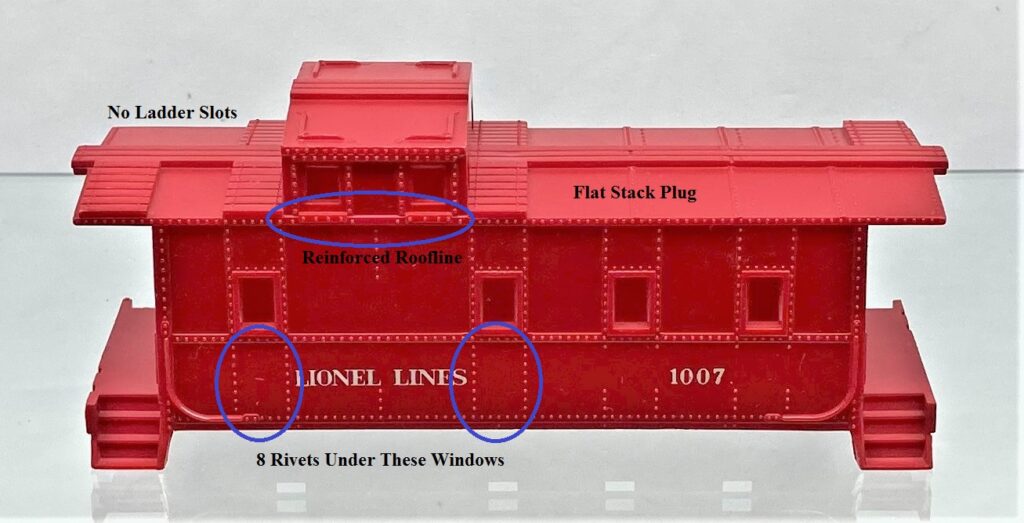

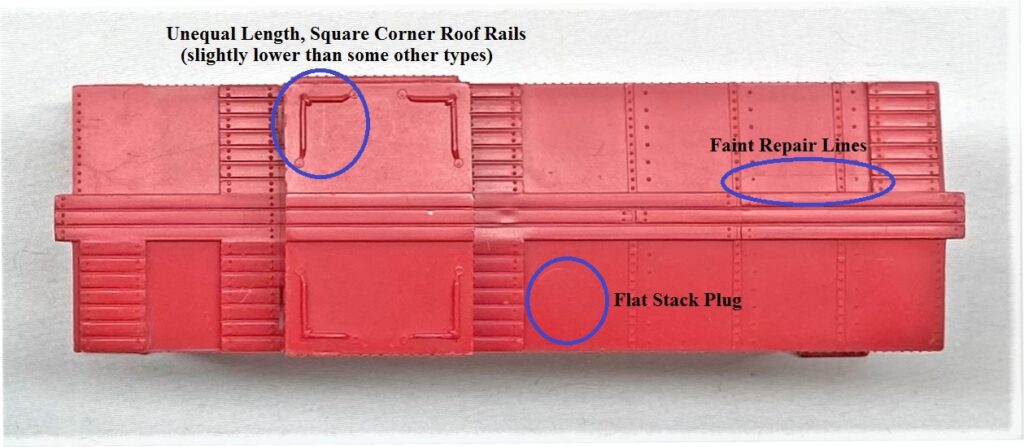

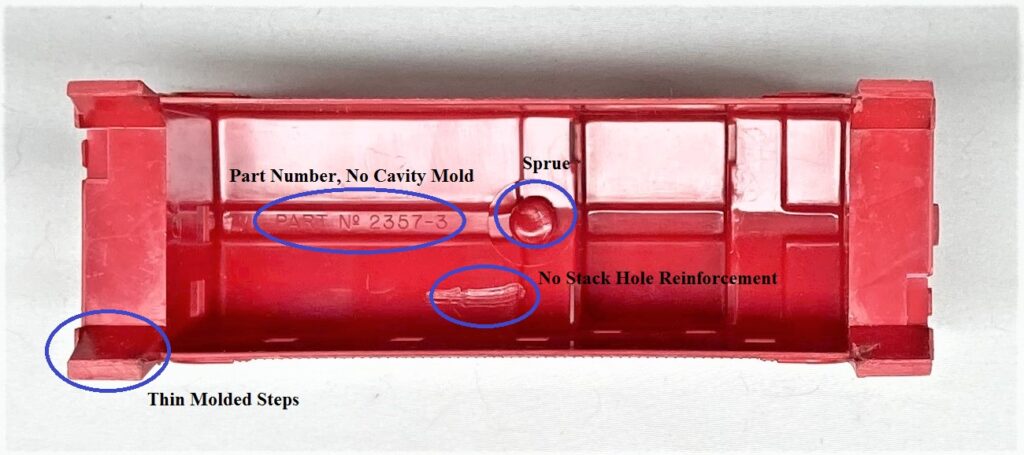

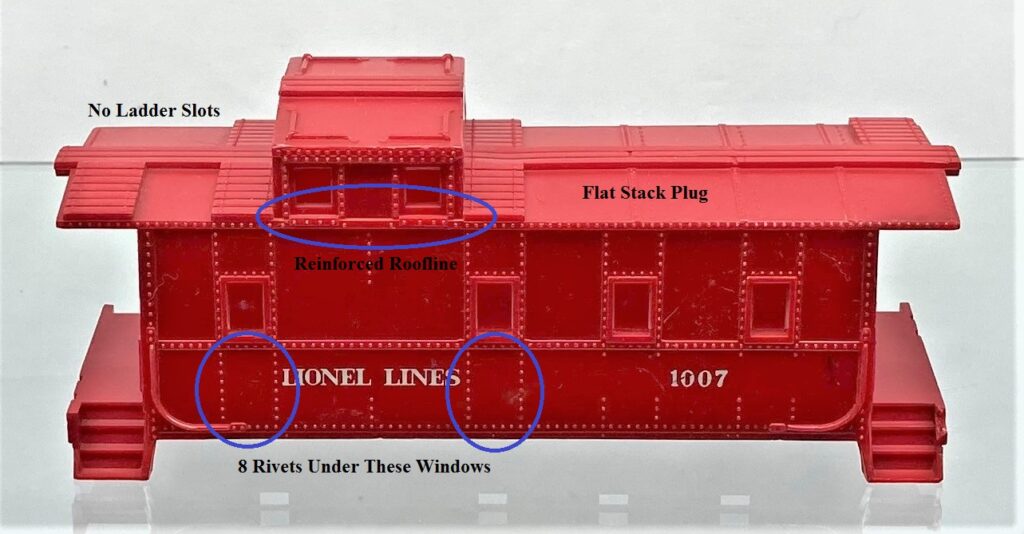

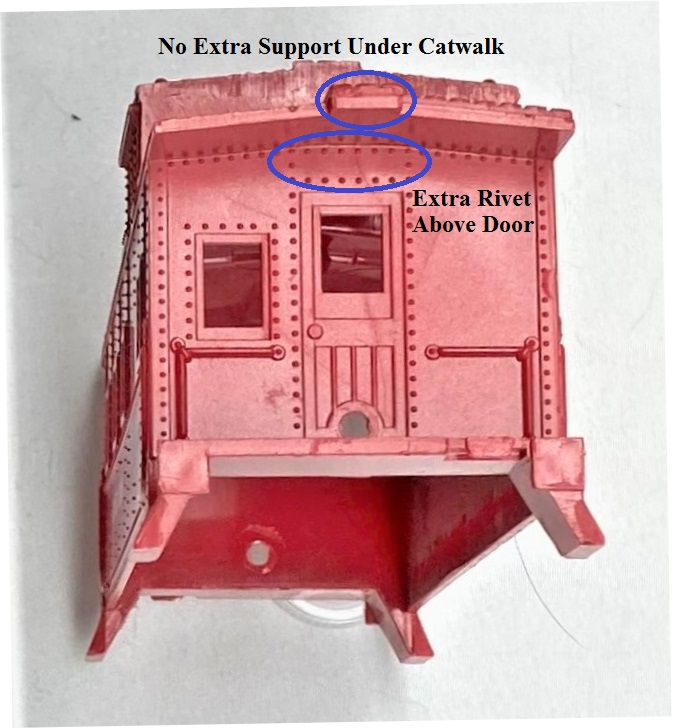

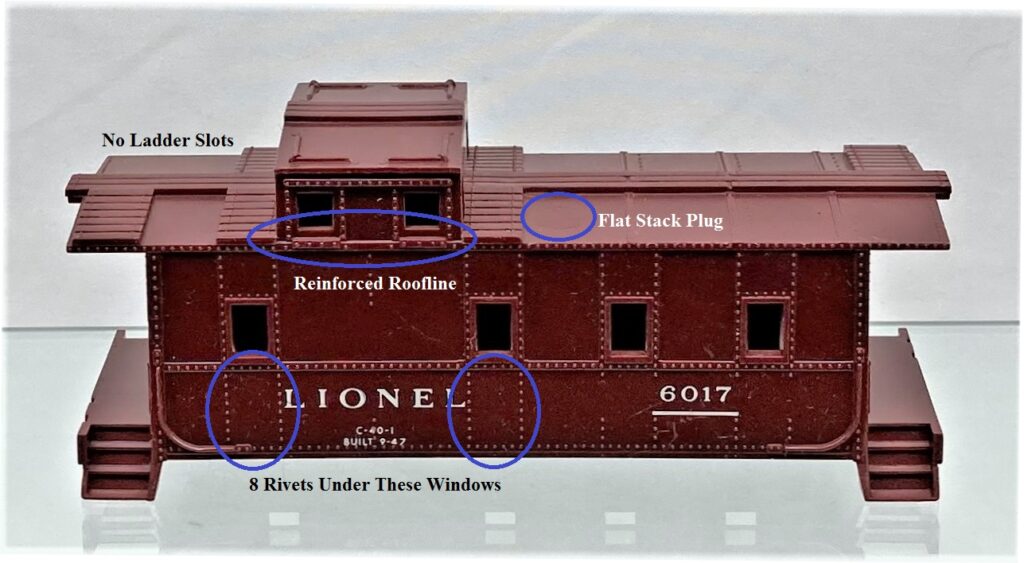

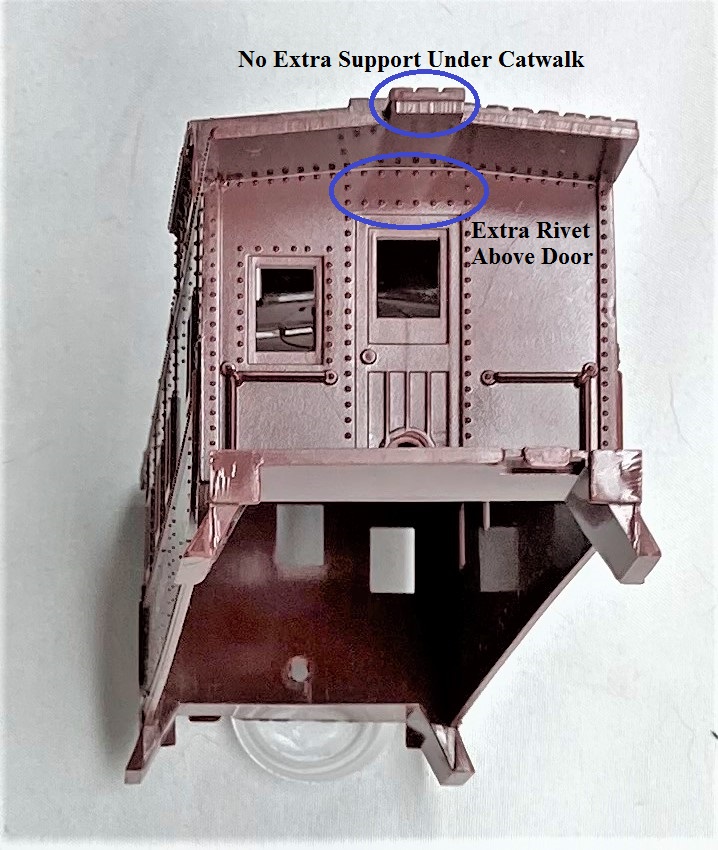

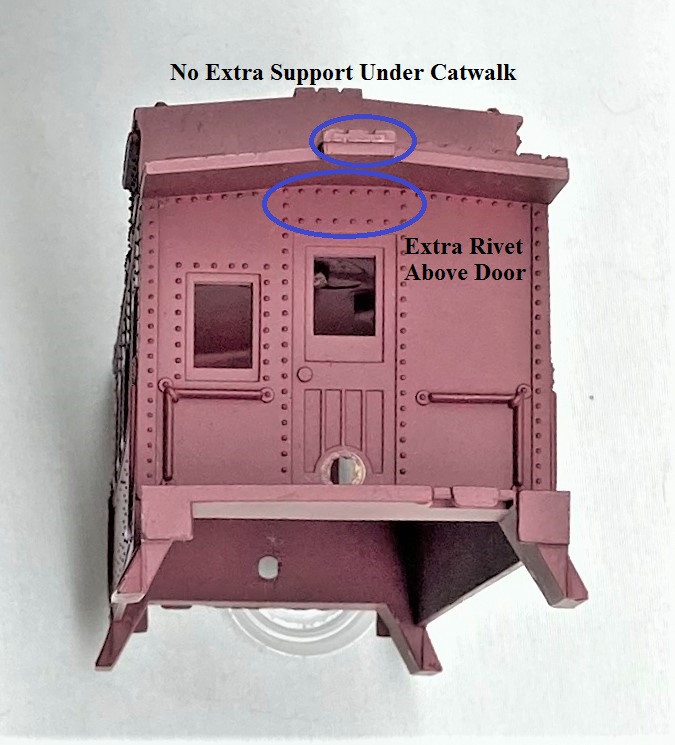

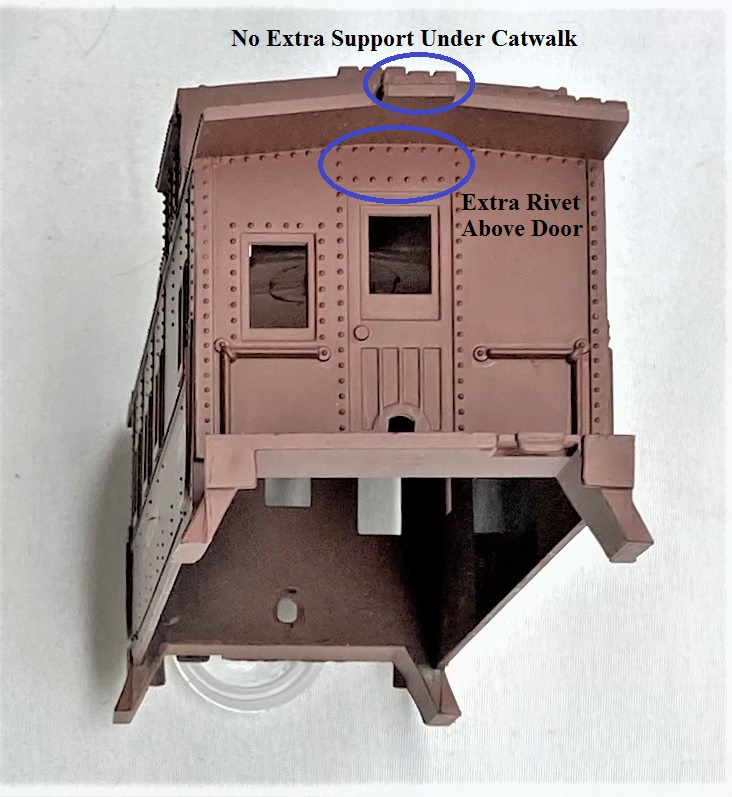

TYPE 3 C 1948 – 1949

produced in a single cavity mold

comes unpainted

without raised extra catwalk board

– without ladder slots

– has flat stack plug

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

has unequal length railings meeting at right angels, slightly lower than some other types

has faint repair lines

has flat stack plug

has part number, no cavity mold number

has sprue

without reinforced stack hole

has thin molded steps

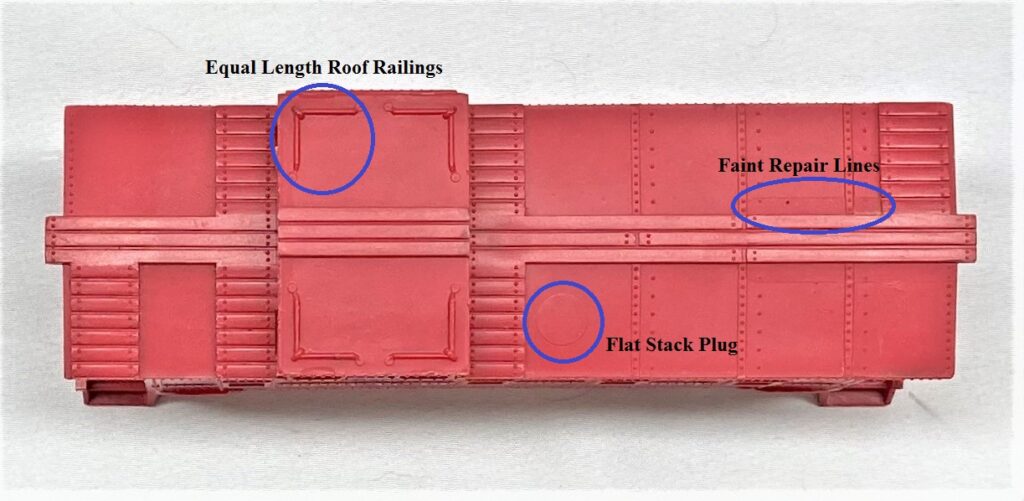

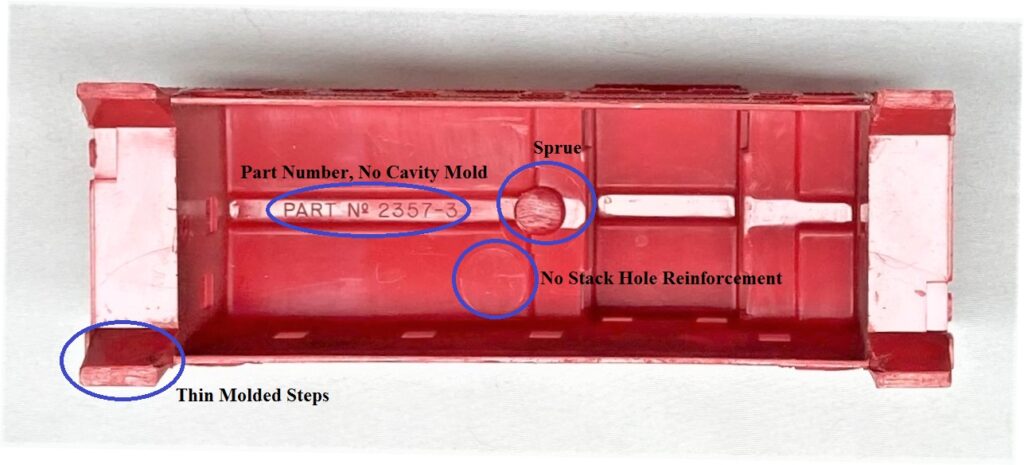

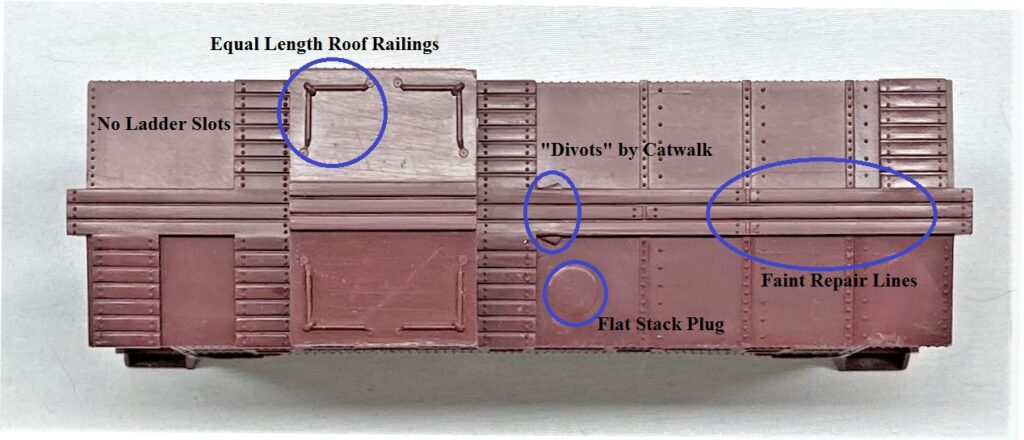

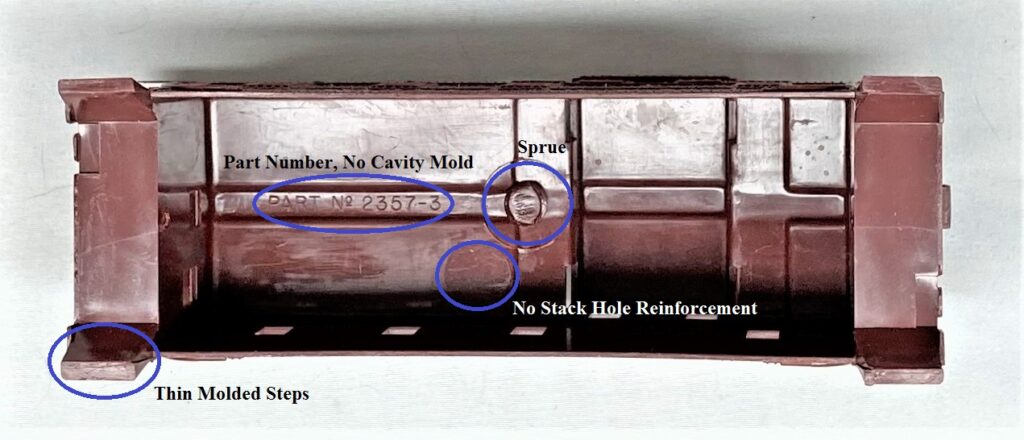

TYPE 3D 1950 – 1955

produced in a single cavity mold

comes unpainted

without raised extra catwalk board

– without ladder slots

– has flat stack plug

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no support under catwalk

has equal length railings meeting at right angels

has faint repair lines

has flat stack plug

has part number, no cavity mold number

has sprue

without reinforced stack hole

has thin molded steps

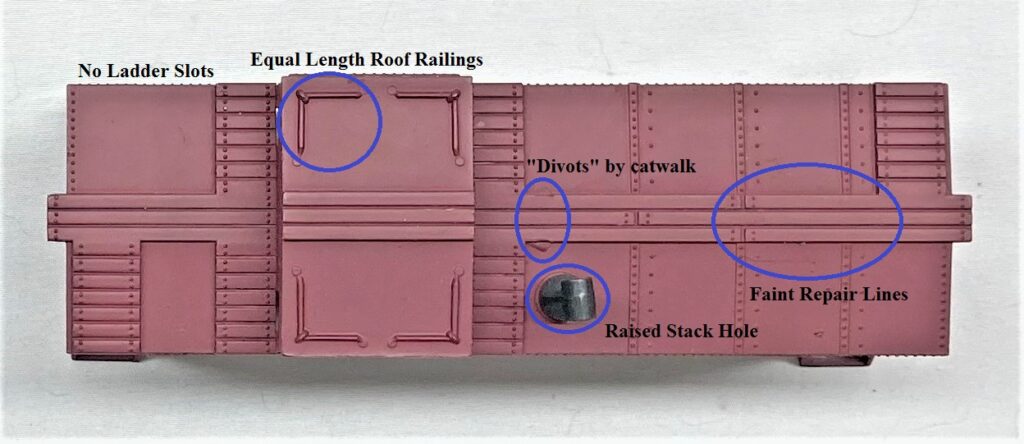

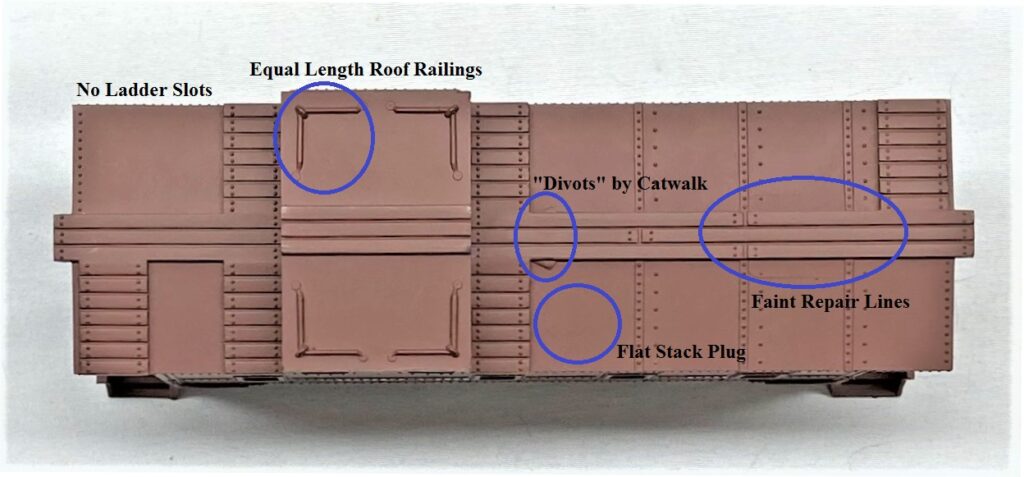

TYPE 3E 1956

produced in a single cavity mold

comes unpainted

without raised extra catwalk board

– without ladder slots

– has flat stack plug

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

“Divots” or wedges added by catwalk

without ladder slots

has equal length railings meeting at right angels

has faint repair lines

has flat stack plug

has part number, no cavity mold number

has sprue

without reinforced stack hole

has thin molded steps

TYPE 3F 1956

produced in a single cavity mold

comes unpainted

without raised extra catwalk board

– without ladder slots

– has raised stack hole rim

– has reinforced roofline

– has eight rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

“Divots” or wedges added by catwalk

without ladder slots

has equal length railings meeting at right angels

has faint repair lines

has raised stack hole

has part number, no cavity mold number

has sprue

has reinforced stack hole

has thin molded steps

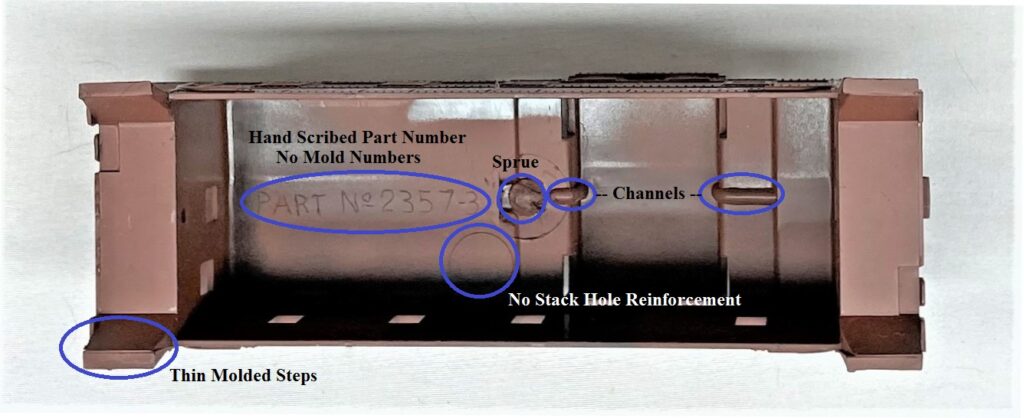

TYPE 3G 1957 – 1959

produced in a single cavity mold

comes painted and unpainted

without raised extra catwalk board

– without ladder slots

– has flat stack plug

– has reinforced roofline

– has four rivets in each of the four row under the first two window from the left

has extra rivet above door

no extra support under catwalk

“Divots” or wedges added by catwalk

without ladder slots

has equal length railings meeting at right angles

has faint repair lines

has raised stack plug

has part number, no cavity mold number

has sprue has channels added

without reinforced stack hole

has thin molded steps

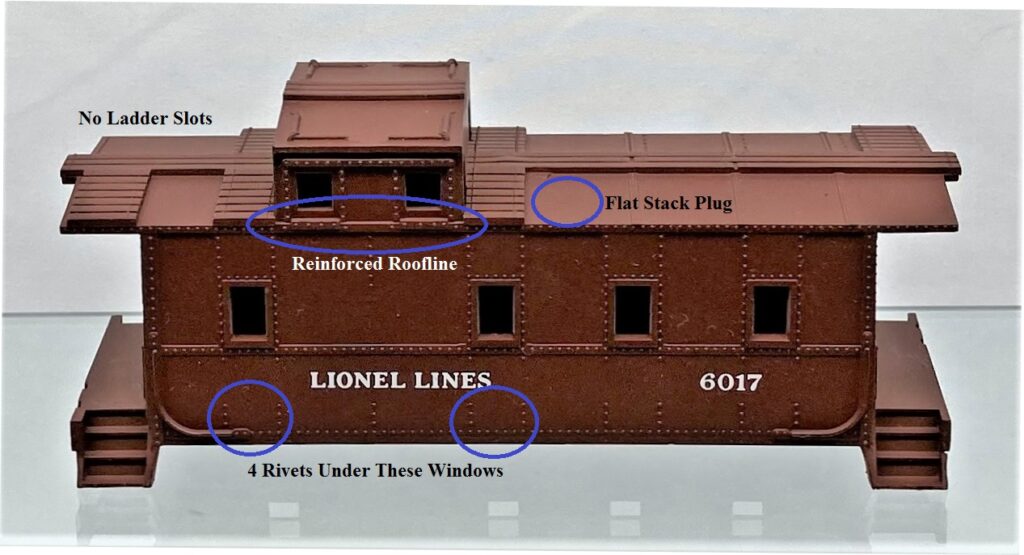

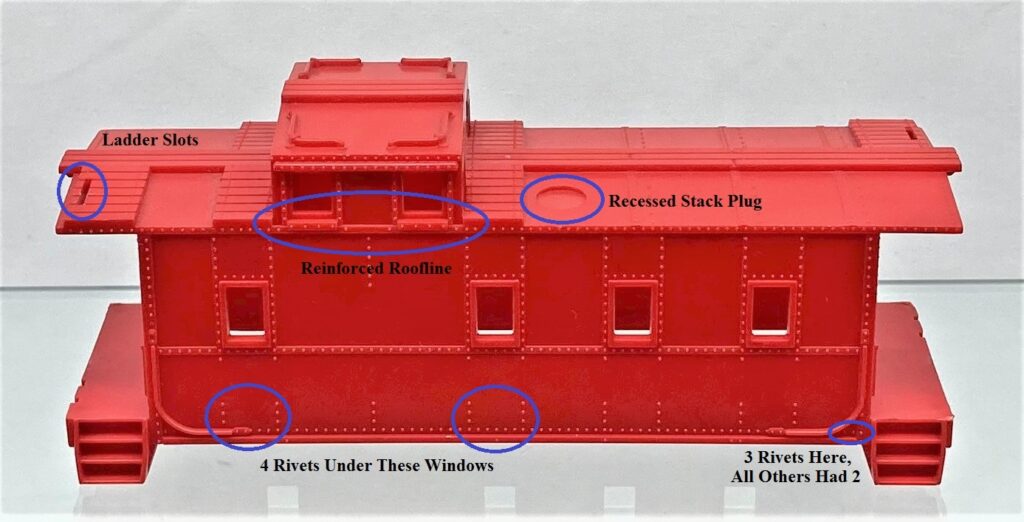

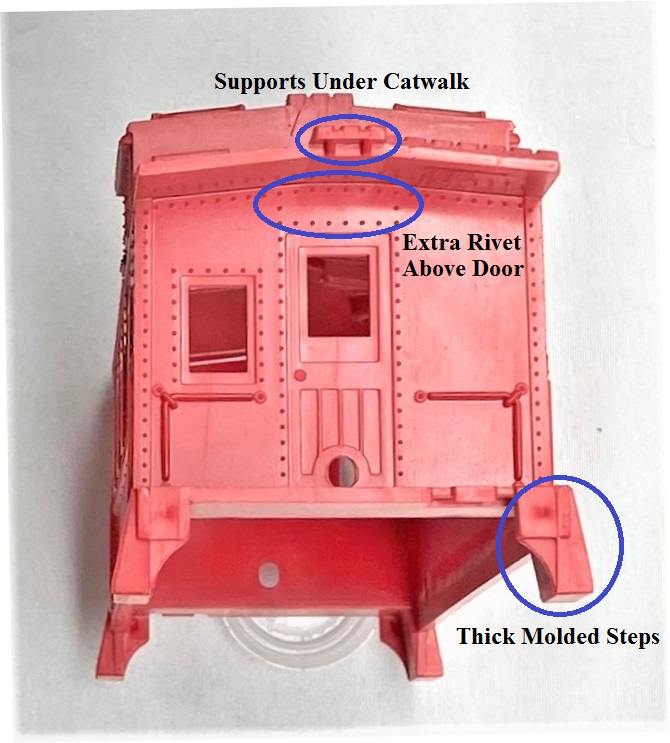

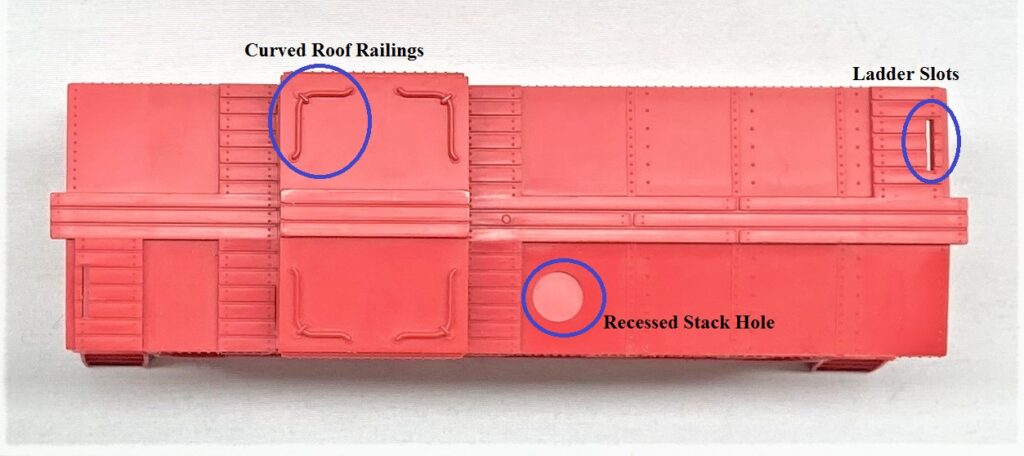

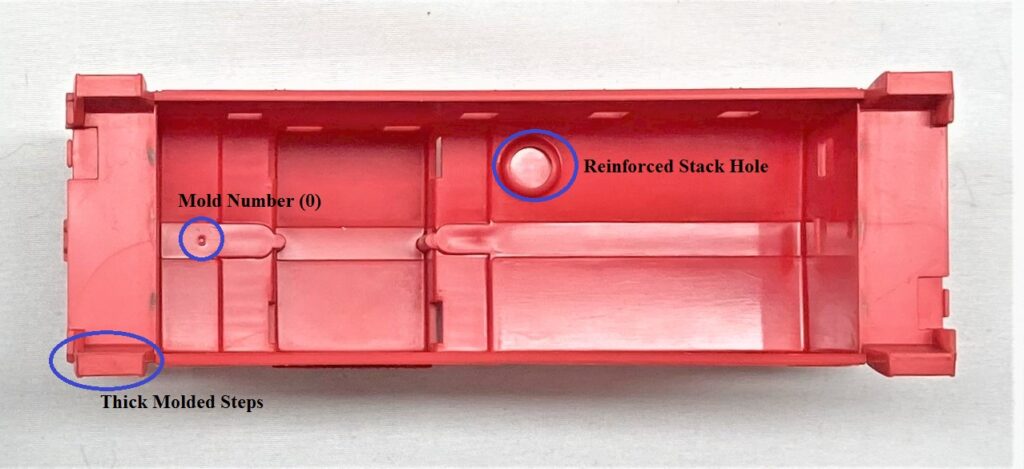

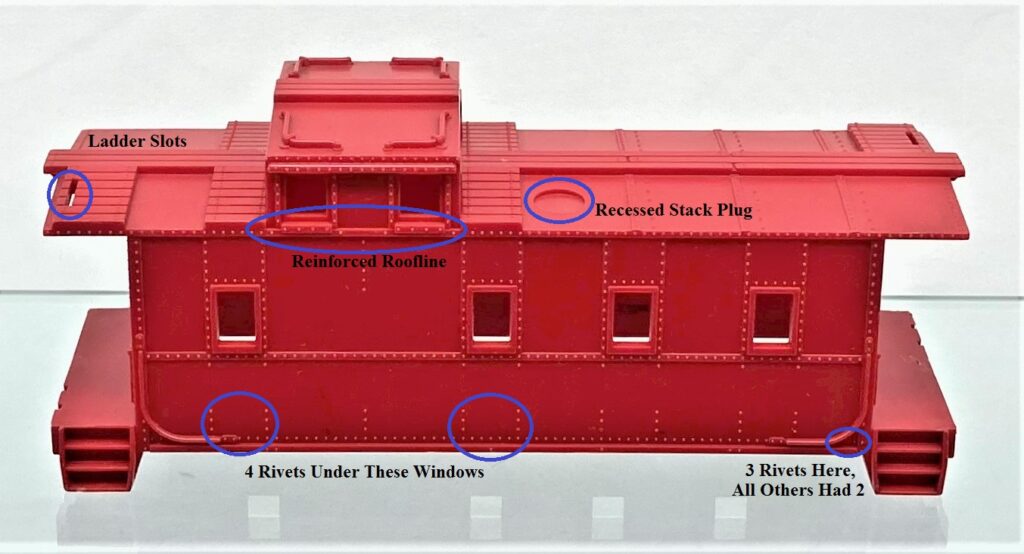

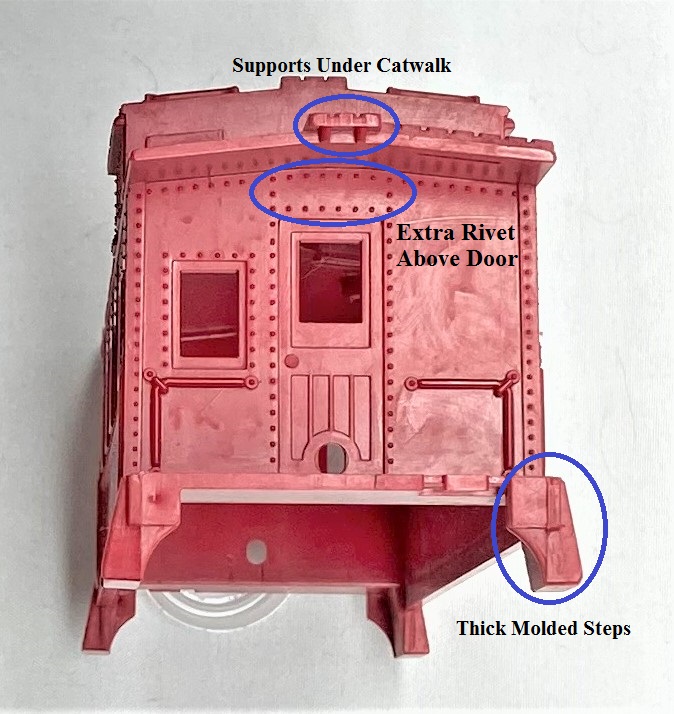

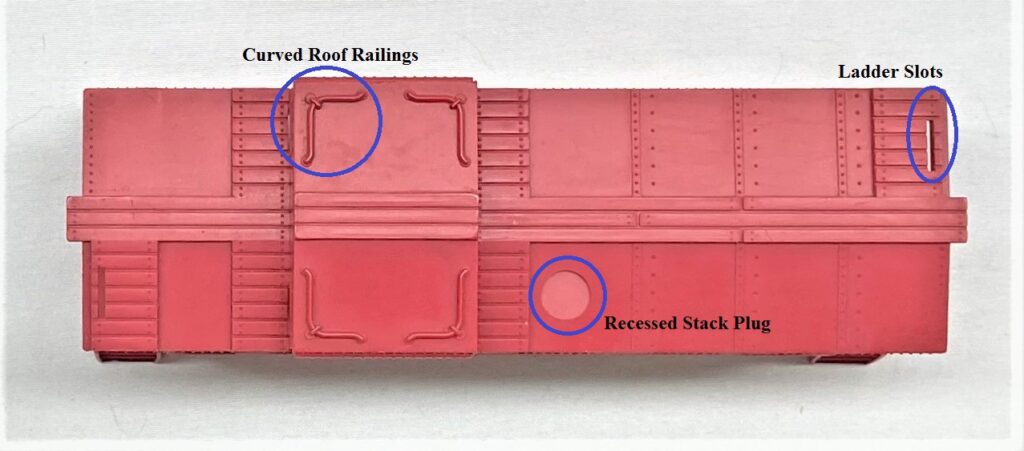

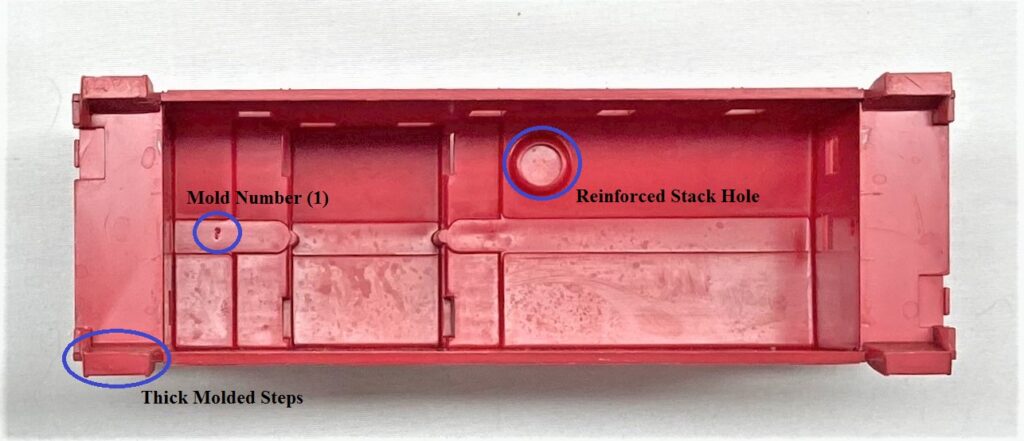

TYPE 4 CAVITY “0” 1960 – 1969

produced in a two cavity mold

comes painted and unpainted

– has ladder slots

– has recessed stack plug

– has reinforced roofline

– has four rivets in each of the four row under the first two window from the left

– has three rivets by molded in grab rails, others before this had two

has extra rivet above door

has support under catwalk

has thick molded steps

has curved roof railings

has recessed stack hole

has ladder slots

has cavity mold number “0”

has reinforced stack hole

has thick molded steps

TYPE 4 CAVITY “1” 1960 – 1969

produced in a two cavity mold

comes painted and unpainted

– has ladder slots

– has recessed stack plug

– has reinforced roofline

– has four rivets in each of the four row under the first two window from the left

– has three rivets by molded in grab rails, others before this had two

has extra rivet above door

has extra support under catwalk

has thick molded steps

has curved roof railings

has recessed stack hole

has ladder slots

has cavity mold number “1”

has reinforced stack hole

has thick molded steps

The following chart summarizes the above shell types

developed by Lyle Leverich

Click HERE to download an EXCEL file of this chart

The following flow chart will guide in ascertaining the type of a shell

Click HERE to download an EXCEL file of this chart

A STUDY ON WHETHER RIVETS TOUCH RAILINGS ON THE LOWER CORNERS OF CABOOSES

The plastic SP Type caboose was introduced by Lionel 75 years ago. Much has been written about it since collectors began to examine the evolution and subsequent variations. This article will hopefully set the record straight about one of the minute details which have been sometimes called a variation.

The author and contributors have over 130 Postwar SP Type caboose variations in their respective collections and have been life-long postwar collectors. We have examined many times that at shows and auctions.

“Variation” as defined by most of the collectors and guides would either be a deliberate change to an item resulting in a significant number of items produced each way, or a significant defect resulting from a damaged tool which persisted through significant production. Examples of the former would be the removal of rivets from certain areas such as on the 6464 boxcars. Examples of the latter include the 6736 Hopper where “Mac’s” face was partially filled in on later production.

First, a little background.

In 1945, Lionel wanted to use plastic injection molded caboose bodies, but it is generally believed that they ran into a problem. The original mold was not designed to allow the body to easily release due to square corners of the cupola. This delayed their introduction until 1947; the pre-war metal type being carried over.

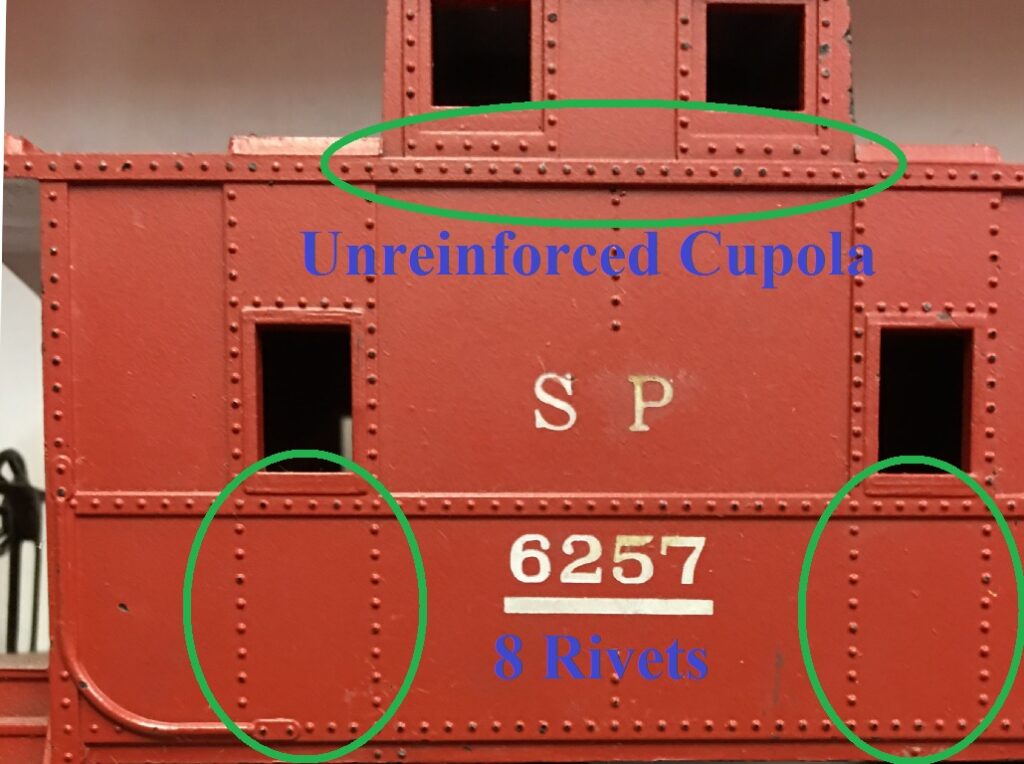

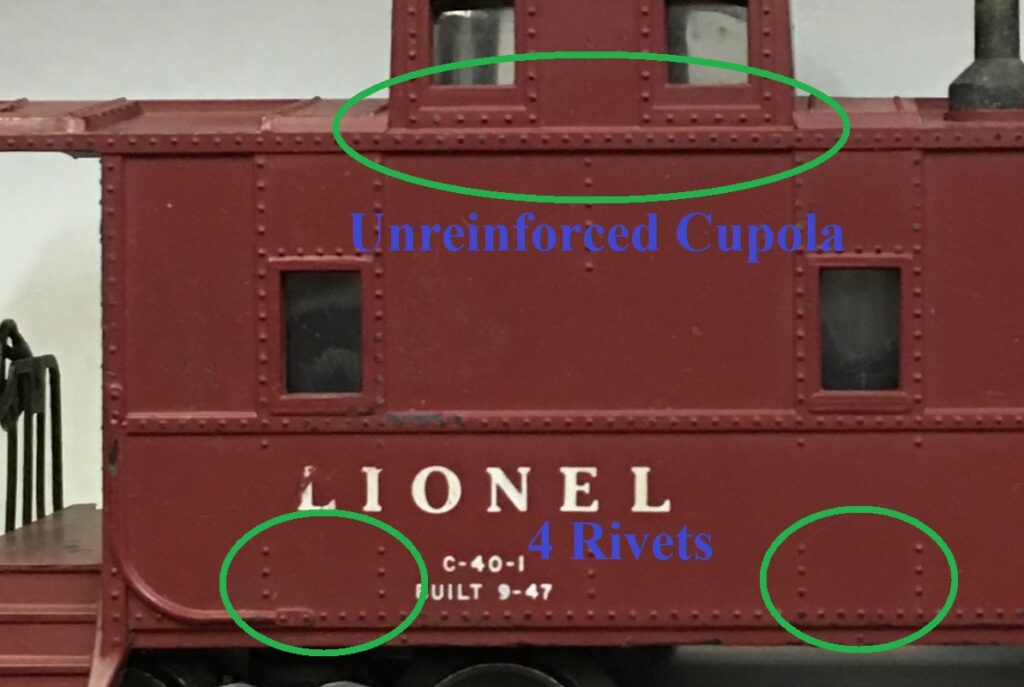

We believe that the earliest SP cabooses were produced in what is called a “single cavity” mold; meaning that one shell is made each time molten plastic is injected into the mold. Without going into all of the details, we can identify these “Type 1” mold bodies most easily since there are 8 vertical rivets in the lower portion of the body below the cupola. See Fig. 1.

In support of this assumption of a one-cavity mold, we submit the fact that there is no identifiable marking either inside or outside of the shells to designate which cavity it came from. The Type 2’s have a “1” or “2” scribed on the inside. Without a way to identify which cavity a shell came from, there would be no way for the factory to identify which mold was producing defective shells.

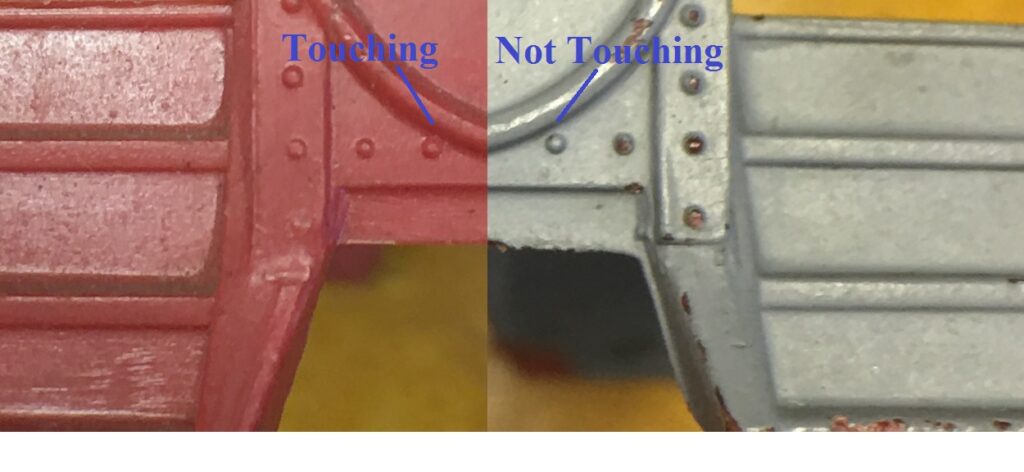

Some studies have claimed that variations exist where the last rivet next to the grab iron either touches it, or a space exists between the rivet and the grab iron. See Fig. 2

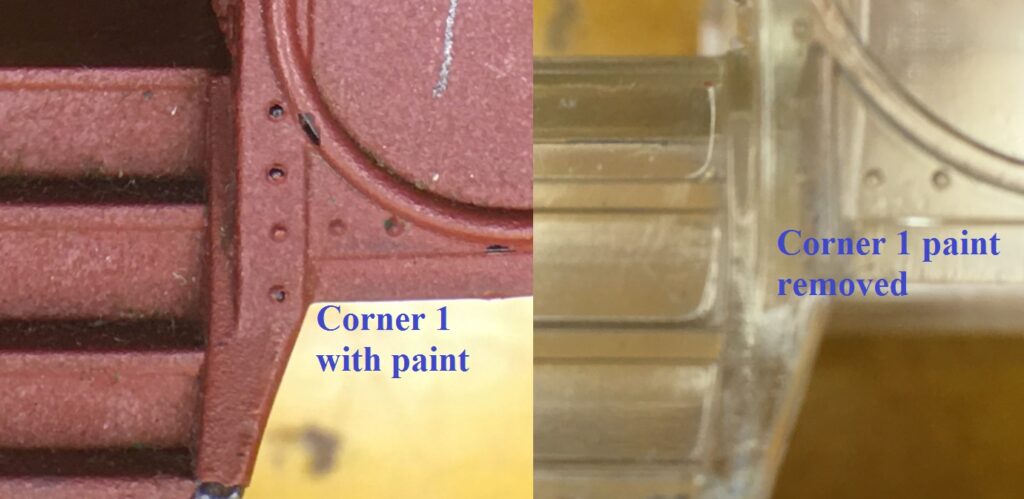

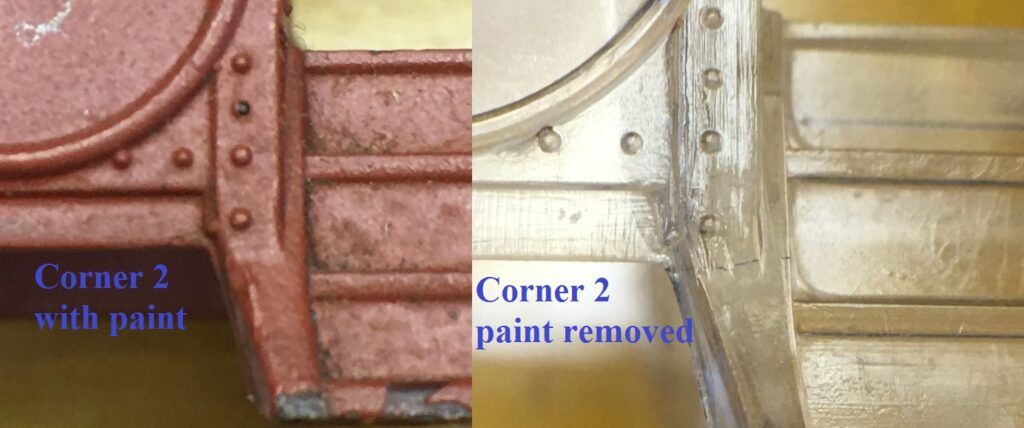

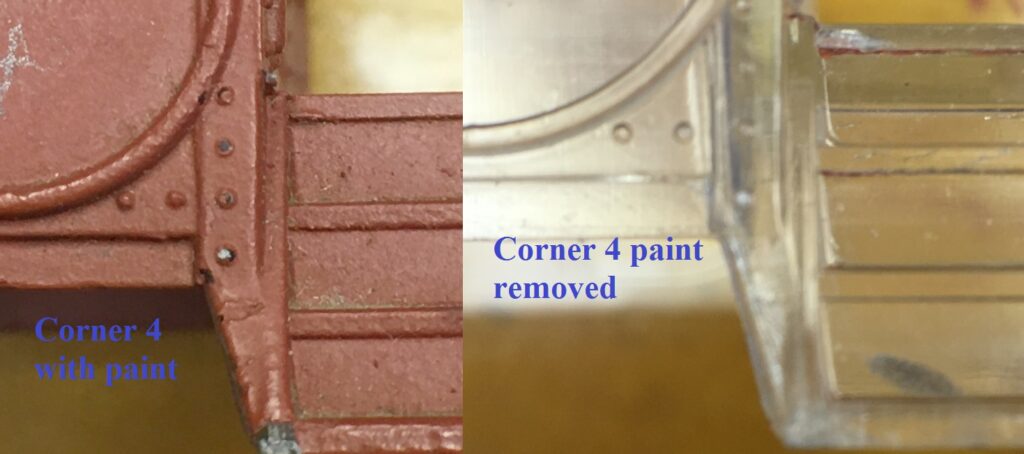

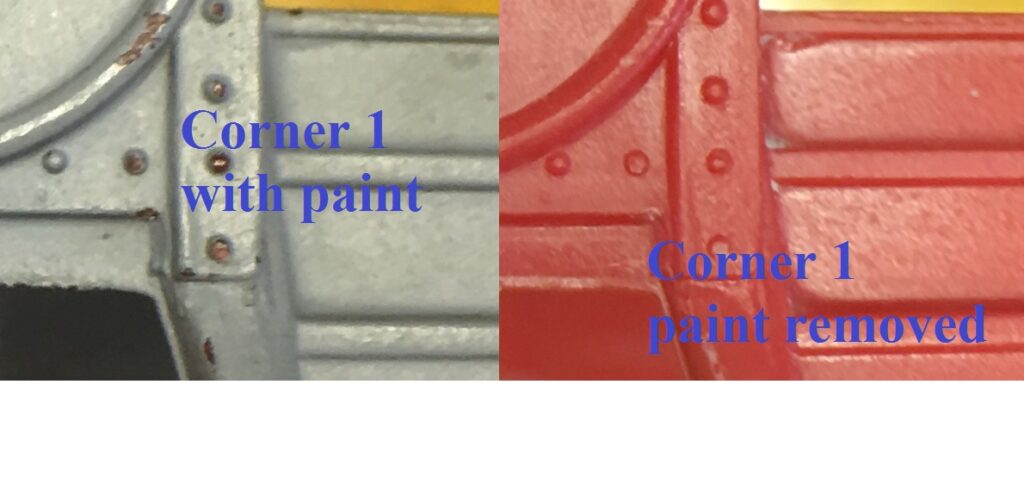

With the exception of the 1007 Scout caboose, most of the Type 1 bodies were painted. It is the author’s belief that this issue of rivet-to-grab iron space was due primarily to paint; then also possibly mold wear. To examine the issue with paint, several damaged shells were photographed up close at the grab iron area, and then the paint carefully stripped using household laundry detergent so as to be certain not to damage the plastic. See Figs 3-6.

We note several things: First, the paint took the longest time to clear from the rivet nearest the grab iron and other spots with similar tight spaces. Clearly, the paint was thicker in those areas. Second, the spacing is not the same in all four corners; one that looked like it touched clearly did not. One appears to touch.

The conclusion here is that this is not a basis for a “variation” given that all Type 1 came from the same mold.

Next, we examine the “Type 2” mold. This mold was known to be a “2 cavity” mold meaning that two (nearly) identical shells were produced for one plastic injection. This mold had a “1” and a “2” scribed on the inside of the roof of the cupola. Type 2 bodies are identified by having only 4 vertical rivets in the lower portion of the body below the cupola, as well as ladder slots and the “non-reinforced cupola roof line”. See Fig. 7.

We looked at an unpainted example of the Type 2 – Mold 2. See Figs. 8-11.

Here we find two rivets seem to touch; two don’t. Again, this would have to hold for all Type 2 – Mold 2 bodies.

Next, we looked at a Type 2 – Mold 1 body that was painted. Then the paint was removed as we did for the Type1. See Figs. 12-15. The result is similar to the Type 1 study; paint does make some look like they touch; others were molded touching.

The conclusion here also is that this is not a basis for a “variation” given that all Type 2 came from one of the same two mold cavities.

The best that can be said is that if one finds an SP caboose where the rivet spacing to the grab iron seems to differ is that it is either paint thickness, tool wear, or maybe even some residue sticking in the dimple that forms the rivet resulting in a smaller, and spaced, rivet.

I wish to thank Craig D. Chidester and Cornucopia of Toy Trains.com for assistance with this study.

Lyle Leverich

INFORMATION

BRAKE WHEELS

The first produced cabooses had 2 brake wheels facing inward. Early in production the production changed to 2 brake wheels facing outward. In 1950 the production changed to 1 brake wheel facing out on the cupola end. In 1955 Lionel dropped the brake wheel altogether.

Inward Facing Brakewheels

Screw Mount

Outward Facing Brakewheels

Screw Mount

One Brakewheel

Screw Mount

No Brakewheels

Screw Mount

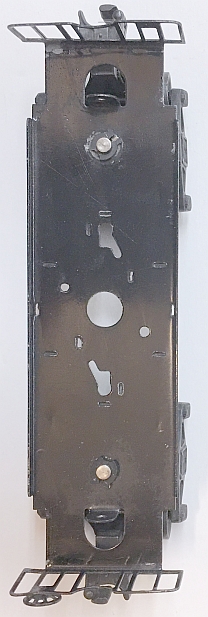

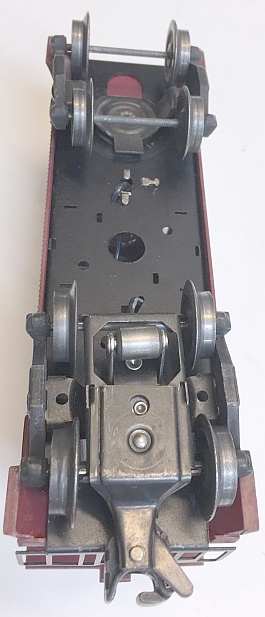

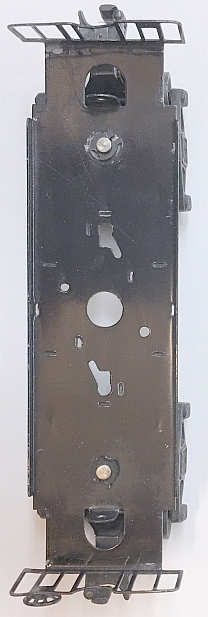

FRAMES

THE MOST IMPORTANT THING TO COMMIT TO MEMORY IS ” FRAMES CAN BE SWITCHED AROUND ” do not chase down a rabbit hole! From 1947 – 1956 there are two frames painted black, one used for lighted models and one for unlighted models both attached by two screws one at each end. In 1957 Lionel brought out the tab frame which was attached by bending two tabs one at each end down. It has end railings at each end and was painted black ( early ) and blackened the most common. In 1963 Lionel added a galvanized tab frame without end railings

Lighted Frame

Unlighted Frame

Painted Tab Frame

Galvanized Tab Frame

No Rails

IN 1950 LIONEL BEGAN USING DIE CAST SMOKE STACKS INSTEAD OF PLASTIC

on left is a plastic smoke stack used prior to 1950, notice it is wider

on right is a diecast smoke stake used in 1950 and thereafter, notice it is narrower

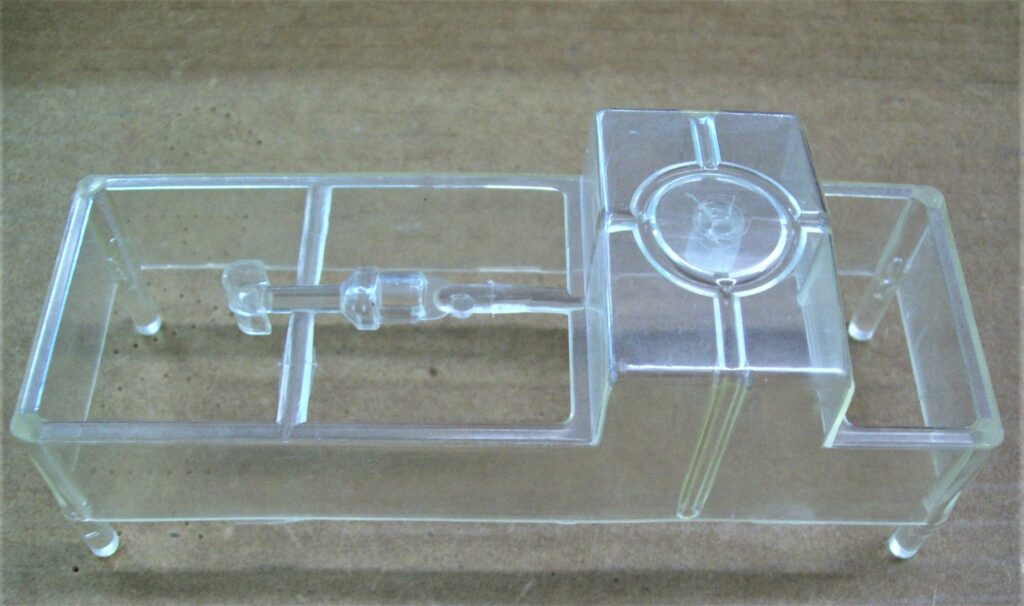

CLEAR PLASTIC SMOKE STACKS

Lionel’s mold for the clear plastic window shell included a clear plastic smoke stack.

Black molded plastic stacks were manufactured also.

VARIATIONS IN LIONEL LETTERING

.

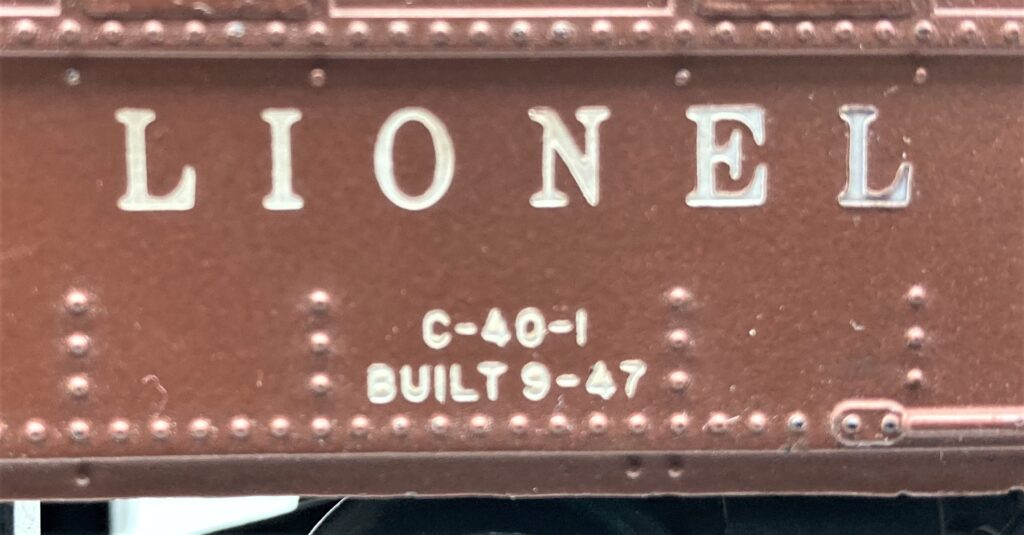

SP 1947 – 1953

lettering can be heat stamped or rubber stamped in white

CIRCLE “L” 1953 – 1956

lettering heat stamped in white

NUMBER RIGHT 1956 – 1961

lettering heat stamped in white

NUMBER LEFT 1956 – 1961

lettering heat stamped in white

VARIATIONS IN STAMPING (heat stamped vs. rubber stamped)

RUBBER STAMPED (R – 9)

on the front right corner note the “7” in 1947 the “7” is complete

all rubber stamped SP cabooses have a complete “7”

UNBROKEN HEAT STAMP (R – 9)

on the front right corner note the “7” in 1947the “7” is complete

the heat stamped as created has a complete “7”

BROKEN HEAT STAMP

on the front right corner note the “7” in 1947 the tail of the “7” is broke off

this is how it remained for the duration of it’s use

WHERE WOULD YOU LIKE TO GO NEXT ?